20 3/4-3000PSI Ram BOP

- Product Item : 7

- Category: Cameron U type Ram BOP

- Ram blowout preventer

- BOP made in China

- 7-21inch bore BOP

- 2000-15000PSI working pressure

20 3/4"-3000PSI Ram BOP

The ram blowout preventer is one of the key elements of the well control system. It is mainly used to control the well head pressure during such operations as drilling, servicing and oil testing to prevent any blow out hazard effectively and ensure safe operations. Specifically, it can be used for the following operations:

² When there is a pipe string a well, the circular space between the casing and the drill

pipe could be sealed with matched pipe rams.

² When there isn’t a pipe string in a well, the wellhead could be shut off completely with

Blind rams.

² After the well has been sealed, such special operations as mud circulation, choking, killing and

well washing can be performed through choke and kill manifold connected to spool and side outlet of BOP.

² When used together with the pipe manifold for choking and killing, it can control the

well pressure effectively and achieve near-balance well killing operations.

1. Technical Parameters

1.1. Ram Blowout preventer

Type: FZ-Single Ram Blowout Preventer

2FZ-Double Ram Blowout Preventer

3FZ-Triple Ram Blowout Preventer

Rated Working Pressure: There are six classes of working pressures as listed in the following table.

Table 2 Working Pressure Rating

|

14 MPa(2,000 psi), |

21 MPa (3,000 psi) |

35 MPa (5,000 psi) |

|

70 MPa (10,000 psi) |

105 MPa (15,000 psi) |

140 MPa (20,000 psi) |

1.2. Temperature Grades of Metallic Materials:

Table 3 Temperature Grades of Metallic Materials

|

Temperature Grade Code |

API Code |

Working Temperature Range |

|

T75 |

75 |

-59~121℃(-75~250 ºF) |

|

T20 |

20 |

-29~121℃(-20~250 ºF) |

|

T0 |

00 |

-18~121℃(0~250 ºF) |

1.3. Temperature Grades of Non-metallic Sealing Elements in contact with well bore fluids.

Combinations of two letters are used to indicate the lower limits and the upper limits as described below.

Lower Limit (First Letter) Upper Limit (Second Letter)

A 15ºF(-26℃) A 180ºF(82℃)

B 0ºF(-17.8℃) B 200ºF(93℃)

C 10ºF(-12.2℃) C 220ºF(104℃)

D 20ºF(-6.7℃) D 250ºF(121℃)

E 30ºF(-1℃) E 300ºF(149℃)

X 40ºF(4℃) X 180ºF(82℃)

For example, AB represents a temperature grade ranging from -26℃ to 93℃. The specific temperature grade is marked with a code on the sealing member.

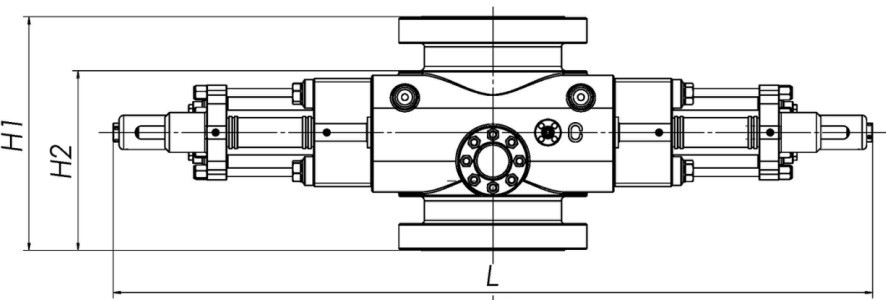

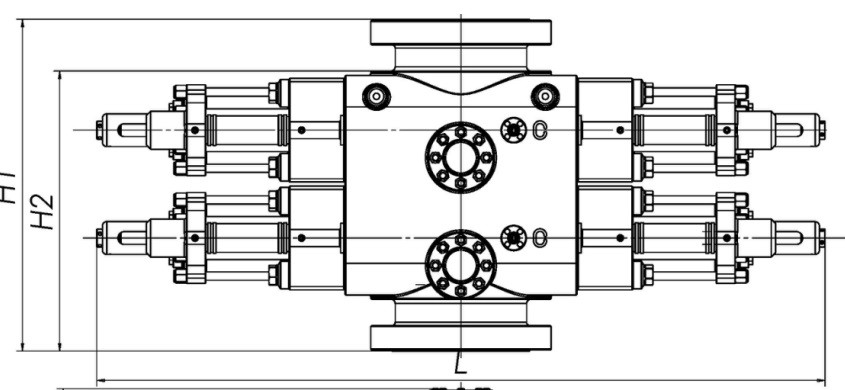

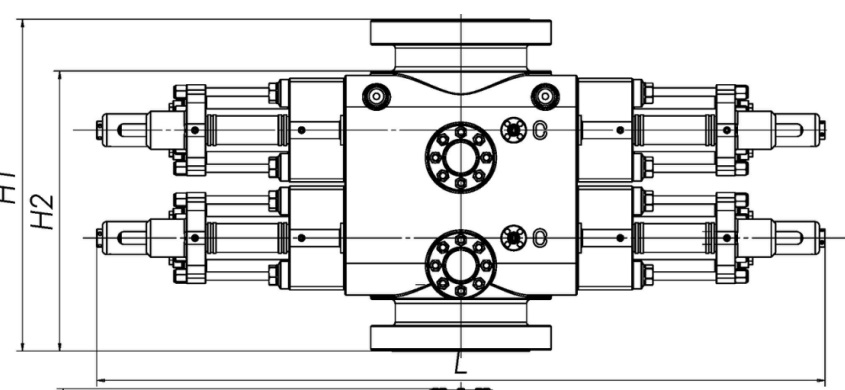

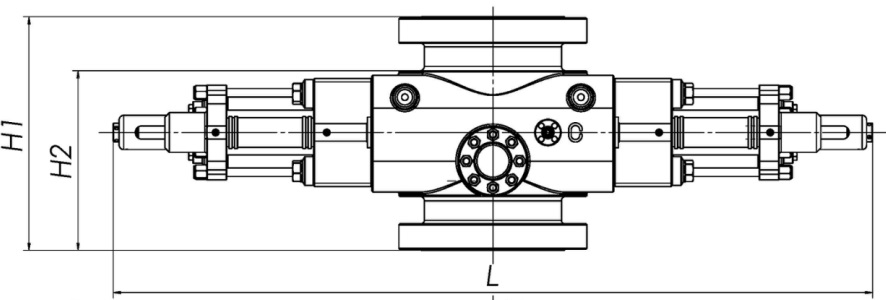

1.4. Technical Parameters of the Ram Blowout Preventer

Table 4 Parameters of Ram Blowout Preventer

|

Item |

Single Ram Blowout Preventer |

Double Ram Blowout Preventer |

||

|

Model |

20 3/4″-3000psi |

20 3/4″-3000psi |

||

|

Top Connection |

Studded |

Flanged |

Studded |

Flanged |

|

Bottom Connection |

Flanged |

Flanged |

Flanged |

Flanged |

|

Weight Kg |

5980 |

6345 |

11675 |

12040 |

|

Length (L) mm |

3550 |

3550 |

3550 |

3550 |

|

Height (H) mm |

815 |

1060 |

1325 |

1570 |

|

Width (W) mm |

1461 |

1461 |

1461 |

1461 |

|

Bore Size |

527 mm (20 3/4″) |

|||

|

Shell Test Pressure |

31.5 MPa (4,500 psi) |

|||

|

Rated Working Pressure |

21MPa (3,000 psi) |

|||

|

Hydraulic Control System Test Pressure |

31.5 MPa(4,500 psi) |

|||

|

Hydraulic Control System Working Pressure |

21 MPa(3,000 psi) |

|||

|

Recommended Hydraulic Control Operating Pressure |

8.4~10 .5 MPa(1,200~1,500 psi) |

|||

|

Opening volume for one set of Ram |

53.9L |

|||

|

Closing volume for one set of Ram |

56.2L |

|||

|

Hydraulic Port |

1"NPT |

|||

|

Side Outlet note |

4 1/16″-5000 psi(or customer option) |

|||

|

Temperature Grade note |

T20(-29~121℃) (or customer option) |

|||

|

Closure Ratio |

1:10.8 |

|||

|

Other Descriptions: The blowout preventer is designed and manufactured in accordance with the API Spec 16A edifications. The internal parts of the blowout preventer in contact with the well bore fluids conform to the requirements specified in NACE MR-01-75. |

||||

2. Working Principles

2.1. Principles of opening and closing

When high pressure oil of hydraulic control system comes into the left and right closing chambers of cylinders through oil channel inside body from hydraulic port, the impelling pistons drive ram shafts with ram assemblies to the center of wellhead along ram chamber to close the well. When high pressure oil comes into the left and right opening chambers of cylinders, the impelling pistons drive the ram shafts with ram assemblies away from the center of the wellhead to open the well. The opening and closing is controlled through the reversal valve of the hydraulic control system.

██ Rams closed, bonnets opened

██ Rams opened, bonnets closed

Figure 3 Hydraulic system opening and closing drawing of rams & bonnets

2.2. Principles of well pressure sealing

A ram blowout preventer can only effectively close a well when all the four seals have taken effect. These four seals include the seal between the ram top seal and the body, the seal between the ram front seal and the pipe, the seal between the body and the bonnet, and the seal between the ram shaft and the bonnet.

The ram sealing process is divided into two steps. In the first step the hydraulic oil forces the ram shaft to impel ram packer to deform and seal the front part, and top seal seals top with compressed rubber, so it establishes a primary sealing. In the second step, with the help of the pressure inside the well the rams are impelled from behind to make ram packer deform more and the rams are also impelled from the bottom to let the body adhere tightly to top, thus achieve the reliable sealing. It is called the well pressure assisted sealing effect.

1. Structures and features

1.1. Special features

Ø The opening and closing for both rams and bonnets are all actuated hydraulically by one and same hydraulic path. The bonnets’ opening and rams’ closing are actuated by one and same hydraulic path and action; then the bonnets’ closing and rams’ opening are actuated by one and same hydraulic path and action

Ø Ram assembly: ram bodies are in long-round shape. Ram rubber is divided into two parts: front packer and top seal. This structure is easy and convenient for ram rubber to change. The front packer and top seal could be changed respectively according to damage condition in fact.

Ø Between body and bonnets, a floating well-pressure-assistant-sealing structure is used on bonnet. So need less pre-tighten force is needed, and it’s reliable.

INQUIRY

CATEGORIES

- Cameron U type Ram BOP

- Shaffer type annular BOP and Ram BOP

- hydril type annular BOP GK

- BOP control system Koomey unit

- MSP diverter and shaffer Diverter

- MWD spare Circulating sleeve Centralizer Current-limiting ring

- 3 inch RR Type spring reset relief valve in mud pump F1600 manufacturer

- WPCE Wireline Pressure Control Equipment

- Pneumatic pipe spinner SSW40

- ESP pump Electric Submersible Pump and Spare Parts

- Top drive system

- wellhead equipment

CONTACT US

Name: Steven

Mobile:+8615369805074

Whatsapp:+8613512492572

Email:sales@fengliangpetroleum.com

Add:Binhai New Area, Tianjin City