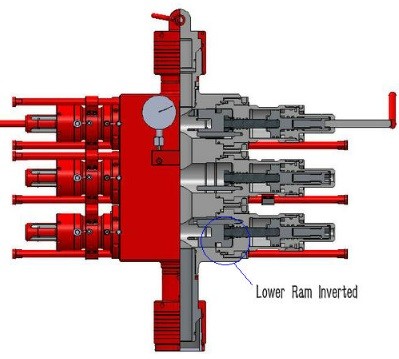

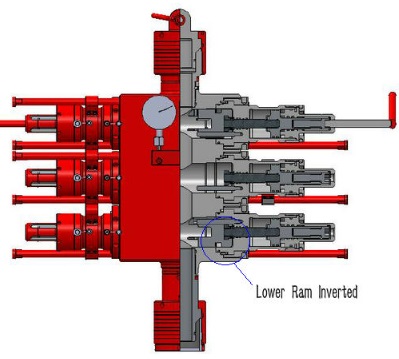

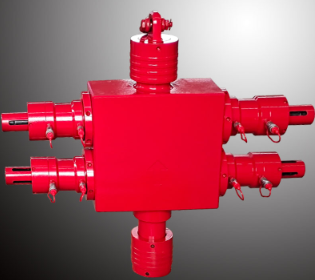

WPCE Hydraulic Double Ram BOP or Hydraulic Triple Ram BOP

- Product Item : 192

- Category: WPCE Wireline Pressure Control Equipment

- WPCE Hydraulic Double Ram BOP

- WPCE Hydraulic triple Ram BOP

- WPCE Hydraulic single Ram BOP

- Wireline Pressure Control Equipment BOP

WPCE Hydraulic Double Ram BOP or Hydraulic Triple Ram BOP

Perhaps no other completions equipment is more critical to the well-being ofyour crew than reliable Blowout Preventers. Wireline BOPs control well pressureduring Wireline or Slickline operations, which can create specific types ofhazards during downhole tasks. Installed between Wellheads and Lubricators,they keep your crews safe during well control events.

The Dual Ram BOP main be recommended apply in Working Pressure 10OOOPsi Oil and Gas Well. If the Working Pressure >10OOOPsi, a Triple RamBOP will be recommended. And Hydraulic BOPs are more commonly appliedthan Manual BOP because of the speed of closing action and ease of operation.

The Dual Ram BOP applied in Wireline Operation and Slickline Operation differin Balance Valve and Ram Assembly normally.But if you need this BOP both fit withWireline and Slickline Operation, we could provide this BOP accordingly.

The difference between the Wireline and Slickline, please refer to the content in Wirelline BOP.

Feature

1) The design and manufacturing of Dual Ram BOP Comply with API Spec-16A, NACE MR O175 and other relevant standards.

2) Forged monobloc construction Body.

3) Compact size, allowing shorter rig-up heights.

4) Hydraulic Cylinder Slide Rods, allowing fast removal of Cylinder for Ram or Seal replacement.

5) Ram position indicator Rods for external indication of the Ram position.

6) Integral Balance Valve Assembly, chemical and grease injection.

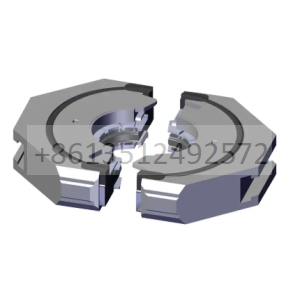

7)Multi Line Ram Assembly allowed for Slickline toO.312".

Main Parameter

1)1.D.

2) Working Pressure

3) Wireline or Slickline Size you applied 4) Upper and Lower Union Required (Bowen or Otis)5)Service Environment(STD or H2S)

6) Working Temperature

The Triple Ram BOPs are mainly recommended to apply in the Well whichWorking Pressure >100OOPsi. Normally, the 3 sets of Ram Assembly of the BOPwill be same size. Sometimes a special Ram Assembly such as Shear Seal Ramcould be applied. In the meantime, it should keep the other 2sets of Rams withsame size.

Triple Ram BOPs or Dual Ram BOPs can be configured with the lower set ofRams inverted. This allows the two sets of Rams to trap a cavity full of greasebetween them of higher pressure, preventing escape up or down. This is mandatory in gas wells, since gas will migrate up the cable between the InnerArmor and Outer Armor. By filling the cavity at a pressure higher than wellheadpressure, the grease fills the spaces and prevents escape.

The Triple Ram BOPapplied in Wireline Operation and Slickline Operation are differin Balance Valve and Ram Assembly normall. Butif you need this BOP both fitwith Wireline and Slickline Operation, we could provide this BOP accordingly.

The difference between the Wireline and Slickline, please refer to the content in Wirelline BOP.

Feature

1) The design and manufacturing of Triple Ram BOP comply with API Spec-16A, NACE MR O175 and other relevant standards.

2)Forged monobloc construction Body.

3) Compact size, allowing shorter rig-up heights.

4) Hydraulic Cylinder Slide Rods, allowing fast removal of Cylinder for Ram or Seal replacement.

5) Ram position indicator Rods for external indication of the Ram position.

6) Integral Balance Valve Assembly, chemical and grease Injection.

7)Multi Line Ram Assembly allowed for Slickline to O.312".

8) Shear-seal Ram Assembly allowed.

INQUIRY

CATEGORIES

- Cameron U type Ram BOP

- Shaffer type annular BOP and Ram BOP

- hydril type annular BOP GK

- BOP control system Koomey unit

- MSP diverter and shaffer Diverter

- MWD spare Circulating sleeve Centralizer Current-limiting ring

- 3 inch RR Type spring reset relief valve in mud pump F1600 manufacturer

- WPCE Wireline Pressure Control Equipment

- Pneumatic pipe spinner SSW40

- ESP pump Electric Submersible Pump and Spare Parts

- Top drive system

- wellhead equipment

CONTACT US

Name: Steven

Mobile:+8615369805074

Whatsapp:+8613512492572

Email:sales@fengliangpetroleum.com

Add:Binhai New Area, Tianjin City