Surface Drilling MSP diverter and shaffer Diverter

29 1/2"-500PSI MSP Hydril Diverter

Bore: 29 1/2"

Working pressure: 500psi

Top connection: MSS 30" CLASS 300 R95 SST studed

Bottom connection:MSS 30" CLASS 300 R95 SST Flanged

Weight(kg):11176

Dimension(mm):1850×1850×1749

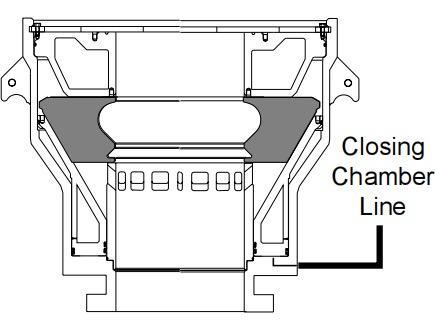

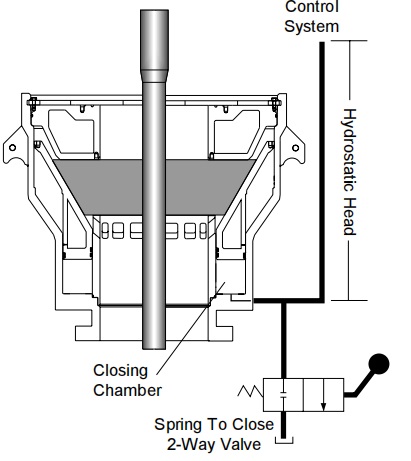

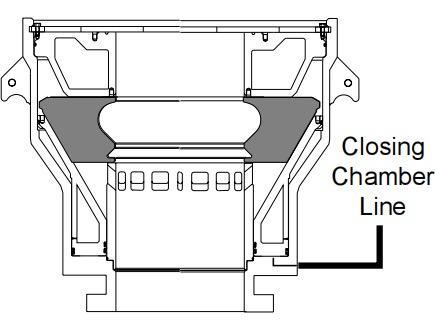

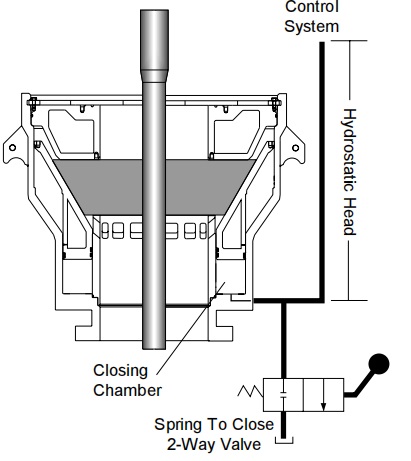

The surface hookup of the MSP shown connects the hydraulic operating pressure to the closing chamber of the BOP.

Pressure applied to the closing chamber raises the piston and effects the initial seal between the packing unit and drill pipe. Closing pressure must be maintained . Well pressure or test pressure also acts on the piston below the sealed off packing unit to decrease the closing force acting on the packing unit. The Control Pressure Graph, Figure 1-9, shows

the relationship of closing pressure and well pressure required to effect optimum seal off for the MSP

29 1/2"-500 diverter. During normal drilling operations, it is recom mended that the pressure regulator valve for the

MSP be set at the initial closing pressure shown for the size pipe being used. This pressure will ensure

that initial seal off is achieved should a "kick" beencountered.

During diverter testing operations, once initial seal off is achieved, closing pressure should be maintained as well pressure is increased.

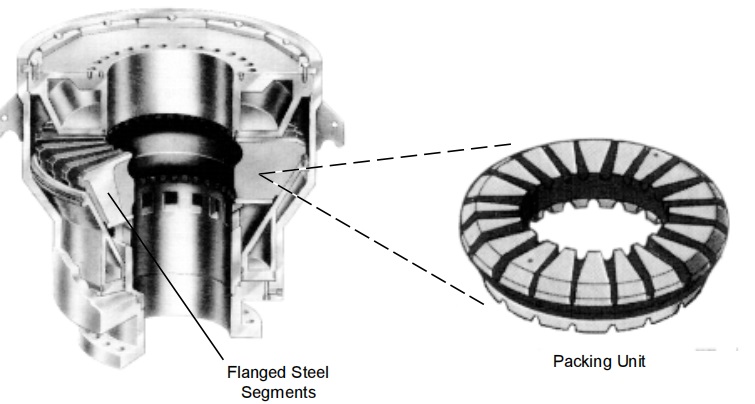

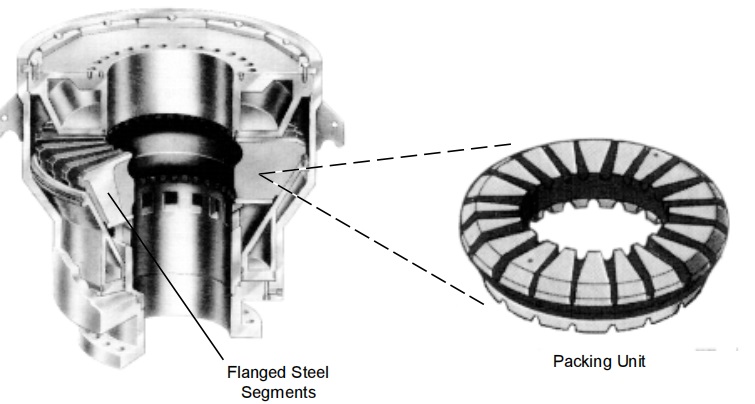

The heart of the MSP diverter is the packing unit (refer to Figure 3-1). The unit is manufactured by Hydril from high

quality rubber, reinforced with flanged steel segments. Each unit has a large volume of tough, feedable rubber to

meet any requirement. The molded-in steel segments have flanges at the top and bottom. These segments anchor the packing unit within the diverter and control rubber extrusion and flow when sealing off well pressures. Since the rubber is

confined and kept under compression, it is resistant to tears and abrasion.

3.1.1 Packing Unit Selection

Because of the importance of the packing unit to the operation of the diverter and to the safety of the crew and

rig, only genuine Hydril packing units should be used as replacements for original equipment. All Hydril packing

units are tested to full rated pressure at the factory as part of a rigid standard acceptance test before being furnished

to the consumer. Packing units for Hydril diverters are manufactured from compounded natural rubber or nitrile rubber.

Natural Rubber

is compounded for drilling with water-base drilling fluids. Natural rubber can be used at

operating temperatures between 30

o

F to 225

o

F (35

o

C to 107

o

C). When properly applied, the compounded natural

rubber packing unit will usually provide the longest service life. This all-black packing unit is identified by a serial

number with the suffix

NR

(refer to Figure 3-1). Nitrile Rubber

(a synthetic compound) is for use with

oil-base or oil-additive drilling fluids. It provides the best service with oil-base muds, when operated at tempera�

tures between 20

o

F to 190

o

F (7

o

C to 88

o

C). The nitrile rubber packing unit is identified by a red colored band and a serial number with the suffix

NBR

. Seals

for Hydril diverters are manufactured from a

special nitrile rubber material which provides long, trouble� free service in sealing against oil gas, or water. Best

service is provided between 20

o

F to 190

o

F (-7

o

C to 88

o

C). Expected H

2

S Service

does not affect selection of

packing unit material. H

2

S service will reduce the service life of rubber products, but the best overall service life is

obtained by matching the packing unit material with the requirements of the specific drilling fluid.

Performance of elastomeric materials can vary significantly, depending on the nature and extent of exposure to

hydrogen sulfide. The operator should monitor pressure sealing integrity frequently to assure no performance deg

radation has occurred. Storage Conditions

are important for realizing the maximum life of the packing unit. Packing units should be stored in a cool, dry dark storage area. Atmosphere, light, and heat accelerate deterioration of rubber goods. It is also essential to practice first-in, first-out when storing packing units. Other significant storage factors are covered in Section 6.3 of this manual.

30"-1000PSI Shaffer Diverter

Bore: 30"

Working pressure: 1000psi

Top connection: MSS SP44 30" CLASS 600 R95 SST studed

Bottom connection:MSS SP44 30" CLASS 600 R95 SST Flanged

Weight(kg):14621

Dimension(mm):1810×1810×1788

21-1/4″-2000psi Hydril MSP Diverter

Bore: 21 1/4″

Working pressure:14Mpa

Top connection: 21-1/4″-2000psi 6BX R73 SST Studded

Bottom connection: 21- 1/4″-2000psi 6BX R73 SST Flanged

Weight(kg):7769

Dimension(mm): 1488×1488×1395

Dongrui Petroleum Machinery Co.,Ltd