ESP pump

- Product Item : 14

- Category: ESP pump Electric Submersible Pump and Spare Parts

- ESP pump

- ESP artificial lift system

- ESP system

- ESP cable

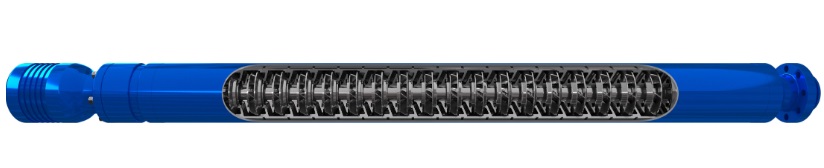

The pump is the core of the ESP artificial lift system. It is in direct contact with the well fluid. However, we are facing challenges brought by different well conditions to the pump every day, not only scaling, solid particles, gas and unstable industrial volume; this drives us to continuously develop new technologies to enhance the reliability of our pumps.

With rich practical experience, Dongrui petroleum engineers take various targeted technical measures to deal with various special well conditions.◆ Impeller and diffuser anti-corrosion coating: The surfaces and flow channels in contact with the well fluid are sprayed with Teflon coating, nickel plating, ceramic coating and other processes to improve the surface hardness and corrosion resistance.

◆ Mixed-phase flow impeller series: The twisted blade design increases the relative velocity liquid flow angle, reduces liquid impact loss and improves the cavitation performance and working efficiency of the impeller.

◆ Wide displacement range pump: The optimized mechanical structure design and material selection of Dongrui petroleum wide displacement pump enable the centrifugal pump to operate in a wider displacement range, and its unique compression assembly form can correctly distribute the increased thrust. It has a higher initial production and faster flow rate decline than the natural flow, and is suitable for wells with gas-containing and abrasive environments, uncertain production capacity or sharp decline in production.

◆ Excessive solid particles in the ESP production process will accelerate pump wear, which may affect the operating life of the system.

To provide advanced wear protection without sacrificing pump efficiency, Dongrui petroleum offers Bidirectional Abrasion-Resistant Modular (BARM) pumps, which use rugged tungsten carbide bearings to enhance radial support in production wells with excessive solid particles or unstable fluid flow. In this design, the axial force of the centrifugal pump is borne by each small section of the Abrasion-Resistant Modular, so the thrust load of the impeller is not transmitted to the protector and motor section of the ESP, thereby improving the total thrust load capacity of the ESP and allowing higher head design. In addition, these "T" bearing sets have a uniquely shaped groove design that has been proven to allow solids to flow fully through and around the sleeves and bushings;This prevents problems such as accelerated wear and heat accumulation associated with sand accumulation in these spaces.

INQUIRY

CATEGORIES

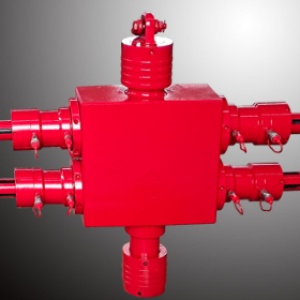

- Cameron U type Ram BOP

- Shaffer type annular BOP and Ram BOP

- hydril type annular BOP GK

- BOP control system Koomey unit

- MSP diverter and shaffer Diverter

- MWD spare Circulating sleeve Centralizer Current-limiting ring

- 3 inch RR Type spring reset relief valve in mud pump F1600 manufacturer

- WPCE Wireline Pressure Control Equipment

- Pneumatic pipe spinner SSW40

- ESP pump Electric Submersible Pump and Spare Parts

- Top drive system

- wellhead equipment

CONTACT US

Name: Steven

Mobile:+8615369805074

Whatsapp:+8613512492572

Email:sales@fengliangpetroleum.com

Add:Binhai New Area, Tianjin City