Grease Injection Control Head

- Category: WPCE Wireline Pressure Control Equipment

- Grease Injection Control Head

- WPCE Grease Injection Control Head

- Grease Injection Control Head

- low pressure Grease Injection Control Head

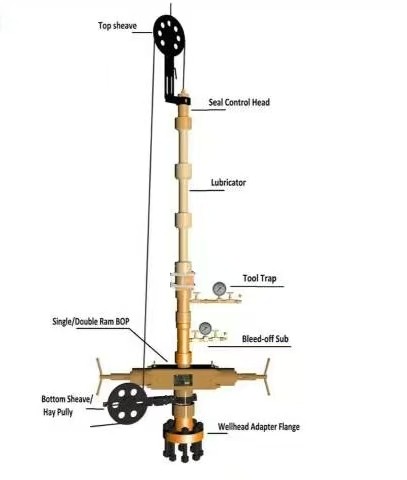

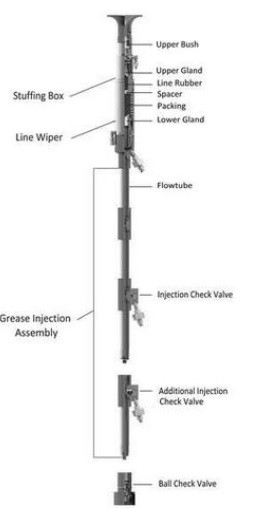

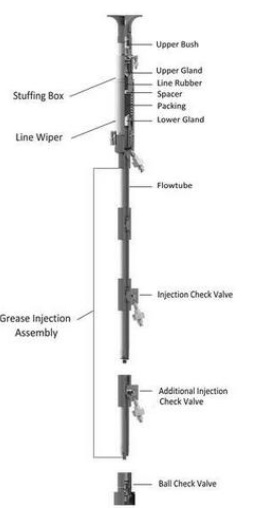

The Grease Injection Control Head is designed to create a seal around static ordynamic wireline, allowing intervention access to wells under pressure.Grease Injection Control Head positioned at the uppermost point of theWireline PCE. It comprises two major sub-assemblies, the Stuffing Box & LineWiper and Grease Injection Assembly. The Stuffing Box is designed to pack-offon a stationary wireline by means of a pack-off rubber, the hydraulic Line Wiperwill wipe excess grease from a moving wireline. The Grease Injection Assemblyis made up of several inner Flow Tubes size to fit tightly around the wireline andOuter Sleeves to support the assembly.

Whenentering a wellunder pressure, viscous grease is injected into the Flow Tubes at a pressure greater than the existing wellpressure. The grease fillsthe annularspace between theinner wallof he Flow Tube and outside suface of the wireline,forminga liquid sealthat contains the wel fluids whileallowing wireline movement.The bottom connection can be mated to Cable Cutter Sub, or a Quick Union, or a Ball Check Valve/Tool Catcher combination.

Feature

1) Range of wire sizes applicable.

2) Max. 15OOOPsi working pressure and H2S service.3) Dual Stuffing Box and Dual Grease Injection Port for high pressureapplication.

4)Recommended Flow Tube clearance + O.003" to 0.008".

Main Parameter

1) Wire size

2)Working Pressure

3) Lower Connection required

4) Service Environment(STD or H2S)

5)Working Temperature

INQUIRY

CATEGORIES

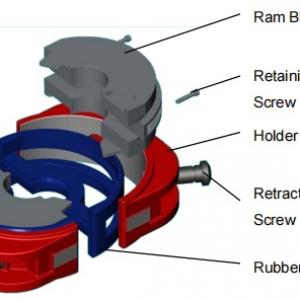

- Cameron U type Ram BOP

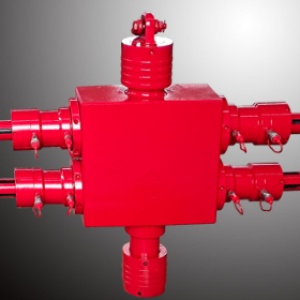

- Shaffer type annular BOP and Ram BOP

- hydril type annular BOP GK

- BOP control system Koomey unit

- MSP diverter and shaffer Diverter

- MWD spare Circulating sleeve Centralizer Current-limiting ring

- 3 inch RR Type spring reset relief valve in mud pump F1600 manufacturer

- WPCE Wireline Pressure Control Equipment

- Pneumatic pipe spinner SSW40

- ESP pump Electric Submersible Pump and Spare Parts

- Top drive system

- wellhead equipment

CONTACT US

Name: Steven

Mobile:+8615369805074

Whatsapp:+8613512492572

Email:sales@fengliangpetroleum.com

Add:Binhai New Area, Tianjin City