Heavy Duty Top Drive System TDS 250 1000 Ton

- Product Item : 100

- Category: Top drive system

- Top Drive System

- 250 tons

- 1000 Ton

- 250tons

Home / Driling Rig / Heavy-Duty Top Drive System (TDS) | 250 – 1000 Ton

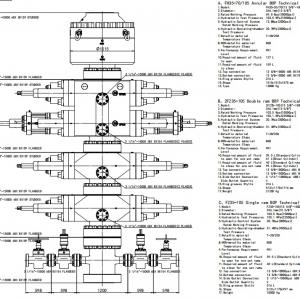

Heavy-Duty Top Drive System (TDS) | 250 – 1000 Ton

dongrui Top Drive System (TDS)

As a premier drilling equipment supplier. We provide high-performance Top Drive Systems (TDS) engineered to handle the most demanding onshore and offshore drilling environments. Our Top Drive solutions are designed to replace traditional Kelly drilling, significantly reducing Non-Productive Time (NPT) and enhancing rig safety.

What is a top drive system?

The top drive drilling system (TDS) is a new-type drilling device designed to replace conventional drilling equipment. Integrating mechanical, electrical, and hydraulic technologies,the TDS features a sophisticated structure and interdisciplinary integration.

As one of the pivotal technologies in the oil drilling sector today. It is hailed as the third revolution in drilling equipment. Representing the highest standards and developmental direction of electromechanical-hydraulic integrated specialized equipment for oil drilling in the 21st century.

The TDS has become a standard configuration in the international drilling industry. It is suitable for cluster directional drilling, high-angle wells. And horizontal wells, and is particularly ideal for deep and ultra-deep wells.

Advantages of the dongrui top drive systems

Control technology is with the mechanical, electronic and hydraulic integration; output parameters of frequency converter are matching with the characteristics of the motor; PLC programme can be designing according to the requirement of the customer. It has functions of monitoring, alarming, self-diagnosis, protection and interlocking, which conform to drilling condition.

Rotating head adopts two ducts to supply oil to tilt hydro cylinder, so link can incline forward and swing backward; as each duct is sealed doubly, the leakage is reduced greatly and the reliability of the equipment is improving; the rotating head can rotate with drilling tools while tripping, so the settlement of the accident is easier.

Simple inserted inner housing structure; back-up tong and IBOP oil cylinder don’t rotate with rotating head.

It has double load channels. The bearing of gearbox bears the weight during drilling and the bearing of rotating head bears the weight during tripping, therefore, the service life of bearings and

main shaft will be prolonged and anti-vertical vibration of drilling string will be improving.

L-type back up tong applied is easy for replacing tong head, tong dies , upper&lower IBOP and saver sub.

The hydraulic pump can be turning off while drilling and directional well drilling, thus the service life of the pump will be prolonging. In case that hydraulic system breaks down, drilling and reaming can be continuing .

Integrated hydraulic system and oil tank are placing on the body of the top drive; the system sends out low heat, which is convenient for installation.

Scientific design, compact structure and reasonable arrangement make onsite maintencance, parts replacement, installation and uninstallation much more easier.

Top drive operating temperature -45°C, storage temperature -60°C.

FAQ Top Drive System (TDS)

Q: Can your Top Drive System be retrofitting to an existing mechanical rig?

A: Yes. We specialize in TDS Retrofitting Solutions. Our engineering team provides custom guide rails and torque tracks to adapt our Top Drive units to traditional derrick structures. Allowing you to upgrade from Kelly drilling with minimal modification.

Q: What is the maintenance cycle for the washpipe and packing assembly?

A: Our high-pressure washpipe assemblies are designing for longevity. Under standard operating conditions, we recommend inspection every 200-300 drilling hours. We provide “Quick-Change” washpipe kits to minimize downtime during replacement.

Q: How do you handle global logistics and installation for such heavy equipment?

A: As a full-service drilling equipment supplier, we manage the entire logistics chain—from export-grade steel crating to global DAP/DDP shipping. We also offer on-site Commissioning & Training services by certified engineers to ensure a seamless startup.

INQUIRY

CATEGORIES

- Cameron U type Ram BOP

- Shaffer type annular BOP and Ram BOP

- hydril type annular BOP GK

- BOP control system Koomey unit

- MSP diverter and shaffer Diverter

- MWD spare Circulating sleeve Centralizer Current-limiting ring

- 3 inch RR Type spring reset relief valve in mud pump F1600 manufacturer

- WPCE Wireline Pressure Control Equipment

- Pneumatic pipe spinner SSW40

- ESP pump Electric Submersible Pump and Spare Parts

- Top drive system

- wellhead equipment

CONTACT US

Name: Steven

Mobile:+8615369805074

Whatsapp:+8613512492572

Email:sales@fengliangpetroleum.com

Add:Binhai New Area, Tianjin City