Big Gear Wheel and Small Gear Shaft for Mud Pump

- Product Item : 123

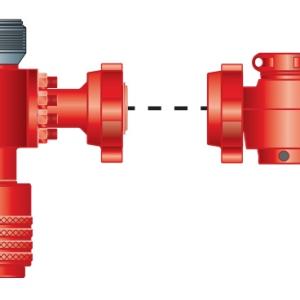

- Category: Pneumatic pipe spinner SSW40

- Big Gear Wheel and Small Gear Shaft for Mud Pump

Big Gear Wheel and Small Gear Shaft for Mud Pump

Description

Pinion shaft and gear shaft

High - quality Forged Shaft

The pinion shaft is forged, providing a solid foundation.

The standard material is AISI 4340 (40CrNiMo), and customized materials are also available to meet diverse application scenarios.

Top - notch Processing Assurance

World - class heat treatment technology and multi - spindle CNC machining are employed to ensure that the product quality of the pinion shaft far exceeds API standards.

Quality Control

Strict Quality Inspection Procedures

Strict quality control and inspection procedures are implemented to endow the pinion shaft components with better performance and a longer service life.

Gear Machining Process

Leading Grinding Process

The herringbone gear is processed by the grinding process. Compared with the gear hobbing process, it offers better quality and a longer service life, with the tooth surface hardness ranging from HRC55 to 60.

Optional Gear Hobbing Process

The gear hobbing process for the herringbone gear is also available as an option according to customers' needs.

Performance Parameters

Suitable for High - pressure Operations

Specifically designed for drilling operations, with a maximum rated pressure of 7500 PSI.

Extremely Long Service Life

It has an extremely long service life, far exceeding API standards.

Compatibility

Full Interchangeability

It is fully interchangeable with major pump models and power end types.

INQUIRY

CATEGORIES

- Cameron U type Ram BOP

- Shaffer type annular BOP and Ram BOP

- hydril type annular BOP GK

- BOP control system Koomey unit

- MSP diverter and shaffer Diverter

- MWD spare Circulating sleeve Centralizer Current-limiting ring

- 3 inch RR Type spring reset relief valve in mud pump F1600 manufacturer

- WPCE Wireline Pressure Control Equipment

- Pneumatic pipe spinner SSW40

- ESP pump Electric Submersible Pump and Spare Parts

- Top drive system

- wellhead equipment

CONTACT US

Name: Steven

Mobile:+8615369805074

Whatsapp:+8613512492572

Email:sales@fengliangpetroleum.com

Add:Binhai New Area, Tianjin City