Choke Manifold Control Console

- Product Item : 19

- Category: BOP control system Koomey unit

- BOP hose 1-5000PSI

- choke manifold choke valve

- kill and choke manifold Control console

Choke manifold control console

as a control assembly in hydraulic choke manifold, can remote-control the open/close of hydraulic choke valve for a long distance and the control panel can indicate the stand-pipe pressure, casing pressure and the opening/ closing condition of hydraulic choke valve as well as the pulse number and frequency of the mud pump if pump-pulse counter equipped, which can keep the pressure under well and is a necessary device to control kick and blowout and perform the pressure control technology in oil/gas well.

manifold control panel manufacturers, the choke manifold control panel meet api 16C specification, with simple operation, convenient maintenance and long service life, is a necessary control device to control well kick and blowout successfully and implement the pressure control of oil and gas.

The choke manifold control panel can remotely control the opening or closing of the hydraulic choke valve, and the standpipe pressure, casing pressure and the valve position span of the hydraulic choke valve can be displayed on the panel of the control box. The transmitters of standpipe pressure, casing pressure and valve position adopt electric/pneumatic signal sensors, which have high sensing accuracy, high shock resistance performance, convenient installation, and meet the requirements of on-site explosion protection.Tianjin Dongrui Petroleum Machinery Co.,Ltd Can produce the choke manifold control console

Function and importance

Well pressure control: The main function is to regulate and control the pressure in the wellbore. This is critical to preventing blowouts, well strikes, etc. and ensuring safe drilling operations.

Fluid Management: The operator uses a control panel to adjust the choke valve to manage the flow of drilling fluids or wellbore fluids to maintain the required pressure levels during drilling or completion.

Emergency Response: In the event of an emergency, such as a sudden increase in pressure or a blowout, the control panel facilitates quick response. The emergency stop system can quickly close the throttle valve and reduce the risk of accidents.

Monitoring and Data Logging: The panel continuously monitors and records data related to key parameters such as pressure, flow rate, etc. This information is invaluable for analyzing well performance and making informed decisions.

Integration with drilling control system: Choke Manifold Control Panel is usually integrated into the overall drilling control system to achieve seamless communication and coordination with other components to form a comprehensive well control strategy.

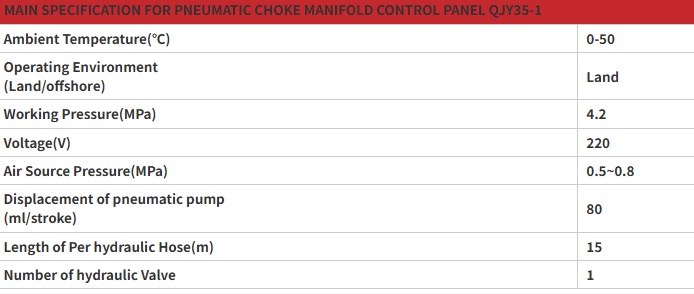

Technology parameter

Gas-source pressure: 0.6MPa

Ambient temperature: --20º--+60º

Working pressure: 3MPa

Quick nipple in gas line: M16*1.5

Quick nipple in oil line: M22*1.5

Hydraulic oil: Anti-cryogenic hydraulic oil

Panel of control console

Casing pressure gauge to indicate actual casing pressure;

Oil-pressure gauge to indicate the oil pressure of the system and output;

Valve-position opening gauge to indicate the opening/closing position of choke valve; .

Gas source pressure gauge to indicate gas source pressure;

Standpipe pressure gauge to indicate actual standpipe pressure;

Nameplate to mark the name of gauge and valve;

Three-position five-way reversal valve to open/close hydraulic choke valve by handle;

INQUIRY

CATEGORIES

- Cameron U type Ram BOP

- Shaffer type annular BOP and Ram BOP

- hydril type annular BOP GK

- BOP control system Koomey unit

- MSP diverter and shaffer Diverter

- MWD spare Circulating sleeve Centralizer Current-limiting ring

- 3 inch RR Type spring reset relief valve in mud pump F1600 manufacturer

- WPCE Wireline Pressure Control Equipment

- Pneumatic pipe spinner SSW40

- ESP pump Electric Submersible Pump and Spare Parts

- Top drive system

- wellhead equipment

CONTACT US

Name: Steven

Mobile:+8615369805074

Whatsapp:+8613512492572

Email:sales@fengliangpetroleum.com

Add:Binhai New Area, Tianjin City