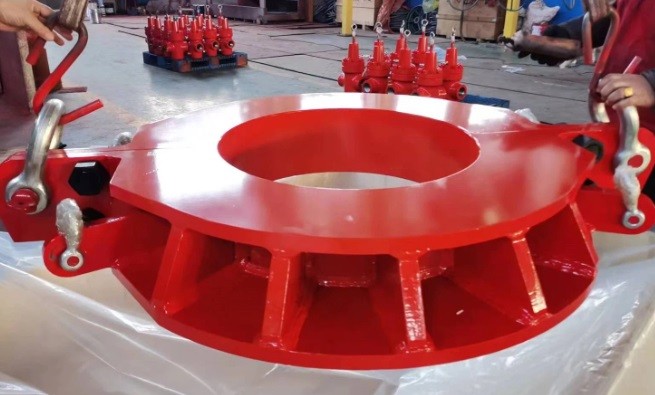

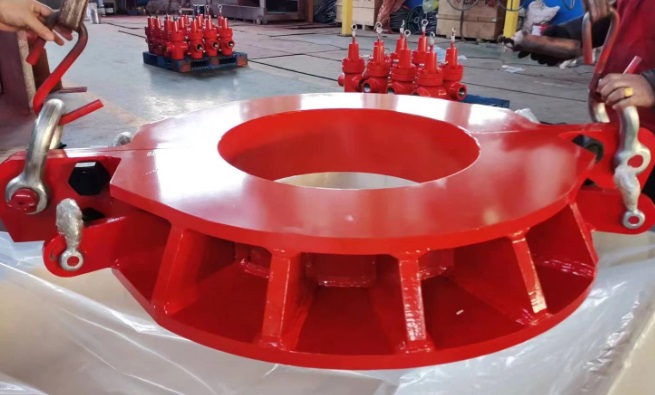

BOP Lifting Clamp

- Product Item : 199

- Category: Shaffer type annular BOP and Ram BOP

- BOP Lifting Clamp

- BOP lifting tool

- BOP lifting frame

- 7-21inch BOP stack

BOP Lifting Clamp

A BOP (Blowout Preventer) lifting clamp, also known as a BOP lifting tool or BOP lifting frame, is a specialized piece of equipment used in the oil and gas industry. Its primary purpose is to securely grip and lift a blowout preventer, which is a critical safety device used in drilling and well-control operations to prevent uncontrolled oil or gas releases from a well. BOP lifting clamps are designed to facilitate the installation, maintenance, and removal of these heavy and bulky devices safely.A BOP (Blowout Preventer) lifting clamp, also known as a BOP lifting tool or BOP lifting frame, is a specialized piece of equipment used in the oil and gas industry. Its primary purpose is to securely grip and lift a blowout preventer, which is a critical safety device used in drilling and well-control operations to prevent uncontrolled oil or gas releases from a well. BOP lifting clamps are designed to facilitate the installation, maintenance, and removal of these heavy and bulky devices safely. Here are some key features and functions of a BOP lifting clamp:

Design: BOP lifting clamps are designed to be robust and durable, capable of withstanding the weight and stress associated with lifting heavy blowout preventers. They are typically constructed from high-strength materials such as steel.

Attachment Mechanism: These clamps are equipped with mechanisms that securely attach to the BOP stack. They may have gripping jaws, hooks, or other attachment points that ensure a strong and stable connection.

Lifting Points: BOP lifting clamps often have multiple lifting points or attachment locations to accommodate different types and sizes of blowout preventers. This versatility allows them to handle various configurations and dimensions of BOPs.

Safety Features: Safety is a top priority when handling heavy and potentially dangerous equipment like blowout preventers. BOP lifting clamps are designed with safety features, such as locking mechanisms or fail-safe devices, to prevent accidental releases during lifting operations.

Compliance: BOP lifting clamps are subject to industry regulations and standards, which may vary by region or country. Operators and contractors must ensure that their lifting equipment complies with these regulations to maintain a safe working environment.

Load Rating: Each BOP lifting clamp is rated for a specific maximum load capacity. It is crucial to use a lifting clamp that is appropriately rated for the weight of the blowout preventer being handled to prevent overloading and potential accidents.

Training and Procedures: Proper training is essential for personnel involved in BOP handling operations. Workers should be trained on how to safely attach, lift, and lower the BOP using the lifting clamp. Standard operating procedures should be followed to minimize risks.

Maintenance: Regular inspection and maintenance of BOP lifting clamps are critical to ensure they remain in good working condition. Any signs of wear, damage, or malfunction should be addressed promptly to maintain safety and operational efficiency.

In summary, a BOP lifting clamp is a specialized tool used in the oil and gas industry to safely and securely lift and handle blowout preventers. These clamps play a vital role in well-control operations and are designed with safety and compliance in mind to prevent accidents and ensure the efficient handling of heavy equipment.

INQUIRY

CATEGORIES

- Cameron U type Ram BOP

- Shaffer type annular BOP and Ram BOP

- hydril type annular BOP GK

- BOP control system Koomey unit

- MSP diverter and shaffer Diverter

- MWD spare Circulating sleeve Centralizer Current-limiting ring

- 3 inch RR Type spring reset relief valve in mud pump F1600 manufacturer

- WPCE Wireline Pressure Control Equipment

- Pneumatic pipe spinner SSW40

- ESP pump Electric Submersible Pump and Spare Parts

- Top drive system

- wellhead equipment

CONTACT US

Name: Steven

Mobile:+8615369805074

Whatsapp:+8613512492572

Email:sales@fengliangpetroleum.com

Add:Binhai New Area, Tianjin City